BECOMING A SUPPLIER TO CSL SEQIRUS

BECOMING A SUPPLIER TO CSL SEQIRUS

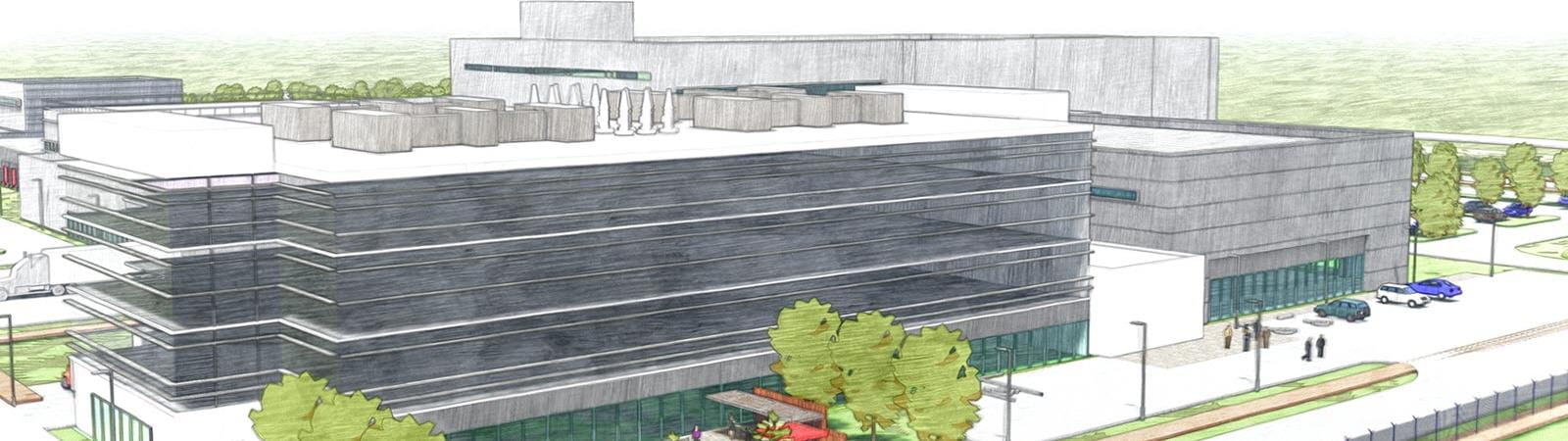

New Cell Culture Facility

Project Overview:

CSL Seqirus, the world’s second largest influenza vaccine provider announced plans to construct a new world-class biotech manufacturing facility in Melbourne, Australia to supply influenza vaccines to Australia and the rest of the world, plus Australian antivenoms and Q-Fever vaccine.

CSL Seqirus is a wholly owned subsidiary of CSL Limited, which will invest more than AUD$800 million in capital expenditure to construct the facility. The building is expected to be operational by mid-2026.

The state-of-the-art facility will use innovative cell-based technology to produce influenza vaccines for use in both influenza pandemics and seasonal vaccination programs – and will be the only cell-based influenza vaccine manufacturing facility in the Southern Hemisphere.

The facility will also manufacture CSL Seqirus’ proprietary adjuvant MF59® - a substance added to some vaccines to help improve immune response and to reduce the amount of antigen needed for each vaccine, enabling more doses to be manufactured more rapidly in a pandemic situation.

In addition, the facility will produce unique products important to Australia’s public health needs – including antivenom for Australian snakes, spiders and marine creatures, and the world’s only human vaccine for Q-Fever.

Project update by February 2024

General description of progress:

- Certificate of Occupancy achieved for Administration facility

- All structural works for all the PNS and FCC facilities complete

- Fit out of PNS and FCC facilities practically complete

- Commissioning well advanced

- Certificate of Occupancy for the site targeted end of April 2024

- Commissioning completion targeted for July 2024

- Qualification completion targeted for December 2024

Our Strategic Sourcing Process

At CSL Seqirus, and across the CSL group, we follow a strategic sourcing process to ensure the chosen supplier is aligned with our overall company values and are capable of meeting innovation, cost, quality and time criteria of the project. Our Strategic sourcing process encompasses engagement of cross-functional teams to ensure a fair, transparent and effective process is undertaken.

Key Categories Supported:

Our Procurement team supports a number of different categories to ensure Project Objectives are achieved and to identify supplier capabilities to support operations of the facility when functional. Below is the indicative list of categories that is of interest to the project.

|

Project phase |

Operation phase |

||

|

Capital goods |

Service |

Direct Spend |

Indirect Spend |

|

Hygienic Vessels |

Electrical installation |

Raw Materials and Packaging |

Building maintenance |

|

Seed & Perfusion Bioreactors |

Automation engineering |

Buffers, Media and Solutions |

Security |

|

Microfluidizer |

Civil construction |

|

Waste Disposal Services |

|

Parts Washers |

Piping installation |

|

Cleaning Services |

|

(Clean in Place) CIP Skids |

Process & Utility Engineering |

|

IT (Hardware, Software and Digital Technology) |

|

Harvest Filter Skid |

Logistic service provider |

|

(Maintenance, Repair & Operations) MRO Services and Supply |

|

Temp Control Unit (TCU) Skids |

IT service |

|

Professional Services (Labour Hire and Business Consultancy) |

|

(Microfiltration) MF unit |

|

|

|

|

Ultracentrifuge |

|

|

Warehousing and Logistic service provider |

|

(Water for injection) WFI Stills |

|

|

Office supplies |

|

Autoclaves |

|

|

Facilities Management |

|

Platform Lifts |

|

|

Building Automation |

|

Lab Isolators |

|

|

Trades (Example: Electrical, Plumbing, Fabrication) |

|

Chromatography columns and Skids |

|

|

|

|

Case packing & palletising |

|

|

|

|

Instruments |

|

|

|

|

Electrical cabinet |

|

|

|

|

Various lab equipment |

|

|

|

Awarded project engineering services and equipment by February 2024:

- Construction: Besix Watpac

- Design engineering: Norman Disney Young

- Automation: Siemens Australia

- Procurement:

- Syringe & Vial Packing Line

- Syringe Filling Line

- Packaging Line

- Process and Utilities vessels

- Bioreactor

- Parts washers and autoclaves

- Valves

- Instruments

- Centrifuge

- Chromatography Skid and Column

- Process Mechanical Installation

- Process Electrical Installation

- Microfluidizer

- CIP Skids

- WFI Still

- PW Generator

- Micro Filtration System

Registration of interest

If your organisation provides products or services in any of the above listed categories or other relevant categories and wish to be considered for any future sourcing events please email your organisation information to Vendorenquiries.banksia@seqirus.com.

Please note invitation to tenders will be made under the sole discretion of CSL Seqirus.

Additional project opportunities can also be found:

Vendor Accreditation Process

The purpose of the Vendor Accreditation Process (VAP) is to assess and pre-qualify vendors to supply equipment, perform work or provide services for CSL at all CSL Seqirus project sites.

Key objectives of the VAP are to:

- Define a harmonized global process for the assessment and approval of vendors supplying equipment, performing work or providing services to all CSL Behring manufacturing sites.

- Define the boundaries and responsibilities of Category Leads in the global sourcing team.

- Establish and maintain a databank of all Vendor assessments and approval status for all CSL entities.

- Introduce a review cycle for all suppliers in order to accommodate the changing market environment.

- Define a method of recourse for disputes.

- List the evaluation criteria and templates.

The assessment consists of the following seven independent sections performed independent of each other:

- Legal Compliance

- Quality (QA/QC)

- Engineering and R&D (Technical)

- Financial

- HS&E

- Supply Chain Integrity

- Trade compliance

The Process Owner is CSL Global Capex Category Lead.